PMV Packaging GmbH

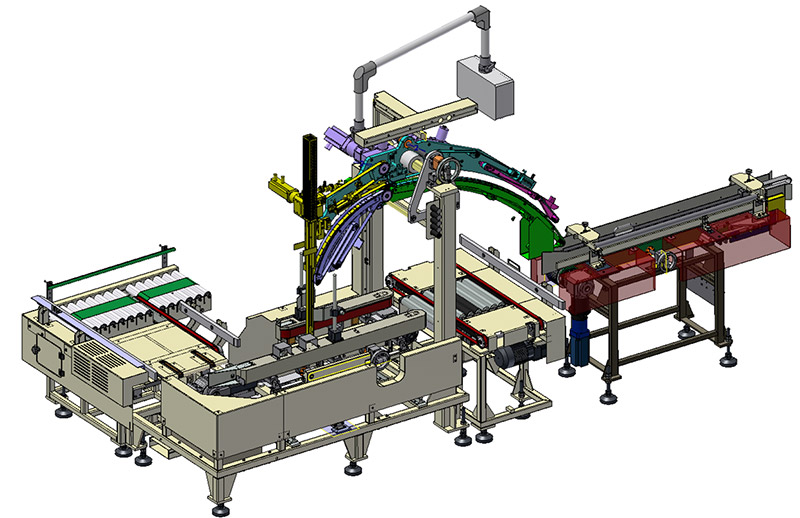

Packing machine – „Q-Pak“

-

Packing machine

Depending on product up to 10 boxes/min. possible -

Size on demand

We fit our machine to your product range and packaging samples -

Less required space

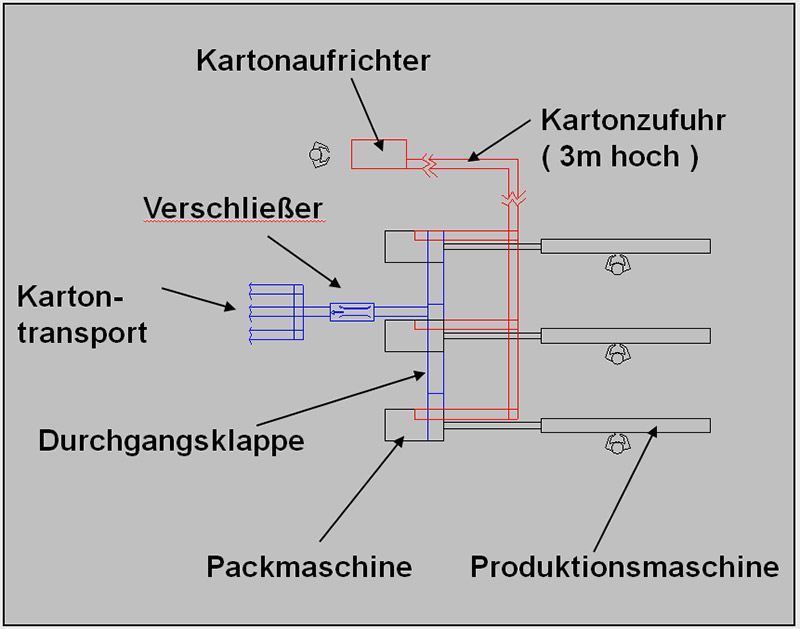

The packing machine is often the decisive factor for the distance of production lines. The standard width of our packing machine including box feed and full box exit is 1.75m only. With this a production line distance of 2.5m and less is possible. -

Automatic box feed

After the empty boxes have arrived in the box feed unit, the boxes are moved and filled automatically. Together with strong partners we can offer the complete empty box transport to the packing machine, including layout of the complete system, flexible and extendible exactly for your needs. -

Automatic full box transport

After the filling process the full box will exit the machine crosswise in the desired direction. We also offer a compact further box transport with a check station and an automatic box closer from our own production. Furthermore together with strong partners we offer a complete full box transport system up to palletising and if required including palletising, flexible and extendible exactly for your needs. -

Automatic production flow control

The material to box is controled automatically. The production machine never has to change the production speed. The packing machine synchronizes itself with the production speed -

Safe box filling

Our toothed belts system grants a safe and slip free transport for a high packaging accuracy. Our belt tightening system keeps the belt tension constant and grants a fast jam removal and belt replacement. -

Further features:

- Perfect accessability from all sides oft he machine

- Easy operating and fast product change via operator panel

- Newest SPS technology in a separate switch gear cabinet

- Additional options available (i.e. labelling)

- Several packing machines are synchronisable in one transport cluster

- Software interface to production machine